Usage detail

Packaging films for IT components, etc., resin modifier, construction materials, etc.

- Overview

- Grade Chart

- Physical properties

- Usage detail

- Product Safety Information

What is the ENTIRA™ AS series?

ENTIRA™ is an anionic specialty resin developed based on the polymer technologies of Dow-Mitsui Polychemicals.

* ENTIRA is a trademark of the Dow Chemical Company or its affiliates.

ENTIRA™ Features of the ENTIRA™ AS Series

ENTIRA can be added to a polyolefin to produce excellent antistatic performance.

- As ENTIRA is a polymer type antistatic agent, it has excellent secondary contamination prevention properties for contents.

- Antistatic effects do not deteriorate over time and are semipermanent.

- As ENTIRA™ disperses well in polyolefins, film has a good outside appearance after blending.

ENTIRA has excellent high frequency sealing properties, making it suitable for sealing thick materials as a substitute for PVC.

ENTIRA has excellent workability and can be processed in regular molding equipment designed for polyolefins.

Grades and Performance of the ENTIRA™ AS Series

| ENTIRA™ AS Series | Comparison Example | |||

|---|---|---|---|---|

| SD100 | MK400 | MK153 | Surfactant | |

| Product Shape | Pellets | Pellets | Pellets | - |

| Main Uses | Main Uses | Main Uses | Used as a standalone resin | Blended with resin |

| Main Processing Methods | Inflation | Inflation, cast, blow and injection molding |

Inflation and blow | - |

| Stability of antistatic performance over time |

○ | ○ | ○ | ✕ |

| Antistatic performance in low humidity |

○ | △ | △ | △ |

| Contamination prevention properties for contents |

△ | ○ | ○ | ✕ |

| Features | Good antistatic properties in low humidity |

Anti-contamination | Anti-contamination and easy cut properties |

- |

← Swipe →

ENTIRA™

| Grade | Test item | Melt flow rate | Density | Tensile stress at break | Tensile breaking strain | Bending rigidity | Durometer A hardness |

Durometer D hardness |

Vicat softening temperature |

Sheet surface resistivity |

Food hygiene ◯: Listed (acquired), ✕: Not listed (not acquired) - :Unknown 1) Dow-Mitsui Polychemicals has not conducted an elution test using a food simulant-solvent. 2) Even if it is listed (acquired), there may be various restrictions and other requirements, please make sure to confirm the details with us. 3) Food hygiene information does not necessarily reflect the latest version of each law or regulation (including voluntary standards). Please be sure to confirm the details with us. |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measurement method | JIS K7210:1999 (190ºC / 2.16 kg load) | JIS K7112 :1999 |

JIS K7161-1:2014 K7161-2:2014*1 |

JIS K7161-1:2014 K7161-2:2014*1 |

JIS K7106 :1995 |

JIS K7215 :1986 |

JIS K7215 :1986*2 |

JIS K7206:1999 |

23℃✕50%RH | |||||

| Unit | g/10min | kg/m3 | Mpa | % | Mpa | - | - | ℃ | Ω/□ | MHLW Positive Lists |

JCII Center JHOSPA Type Confirmation Certificate |

US FDA 21CFR |

European PIM |

|

| SD100 | 5 | 990 | 19 | 500 | 110 | 96 | 54 | 63 | <1.0E+07 | ◯ | ◯ | ◯ | ◯ | |

| MK400 | 1.5 | 970 | 28 | 300 | 280 | 96 | 63 | 60 | <1.0E+07 | ◯ | ◯ | ◯ | ◯ | |

| MK153 | 0.5 | 960 | 26 | 400 | 180 | 97 | 59 | 66 | 1.0E+08 | ◯ | ◯ | ◯ | ◯ | |

← Swipe →

* 1 Tensile test - test piece type and testing speed: JIS K 7161-2 / 1BA / 20

* 2 Measurement instrument: Asker P-2 sensor descent rate: 10.0 mm / s

Note: The data above are typical values and cannot be used as standard values.

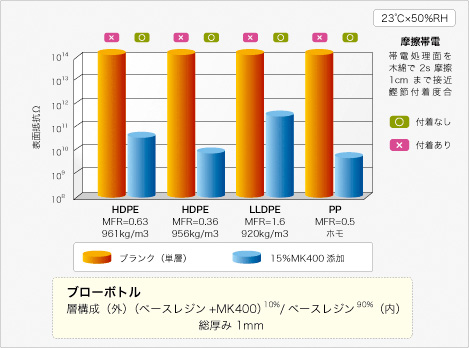

ENTIRA™ AS Series Modifier Performance

Permanent antistatic properties

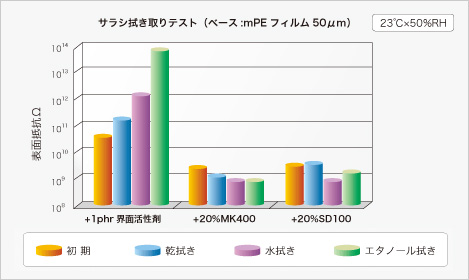

Comparison of antistatic performance when blending MK400

ENTIRA™ AS Series Antistatic Performance

Almost no polystyrene foam beads stuck to a bag using a film blended with ENTIRA™ AS Series.

standalone LLDPE film

Secondary Contamination Prevention Performance

High frequency welder sealing properties

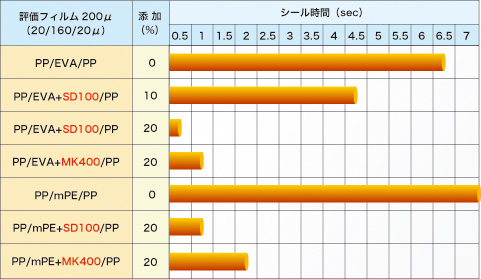

- In the flexible sheet field, PP/EVA/PP and PE/EVA/PE three-layer polyolefin sheets utilizing the high frequency heating properties of EVA are used, but their high frequency weldability is inferior to PVC.

- By adding ENTIRA™ AS Series to the EVA layer, high frequency welding properties can be dramatically improved.

- In addition, adding ENTIRA™ AS Series to polyolefin can give it high frequency welding properties.

Usage detail

Packaging materials using ENTIRA™ AS Series attract less dust and dirt, and also have the effect of preventing adverse effects on contents due to static electricity. In addition, since it is suitable for sealing with high frequency induction heating, we suggest using it for the following products that utilize those properties.

Packaging materials for electronic materials

Applications of ENTIRA™

- Flexible container sheets

- Clean room-compatible packaging materials

- Packaging materials for food and medicines (powders, lightweight materials)

Product Safety Information

1. Medical applications

Please do not use this product for permanent implantation in the human body or for medical applications involving a state of permanent contact with bodily fluids or human tissue (in this case, permanent means 30 days or more.)

Additionally, please consult with Dow-Mitsui Polychemicals in advance if you wish to use the product for other medical applications, such as for a medical device as defined in the Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices.

2. Food packaging applications

Please contact Dow-Mitsui Polychemicals regarding the state of inclusion in (conformity to) domestic and overseas laws or regulations regarding food utensils, containers and packaging materials.

Outside of Japan, Nucrel™ is available from the Dow Chemical Company.