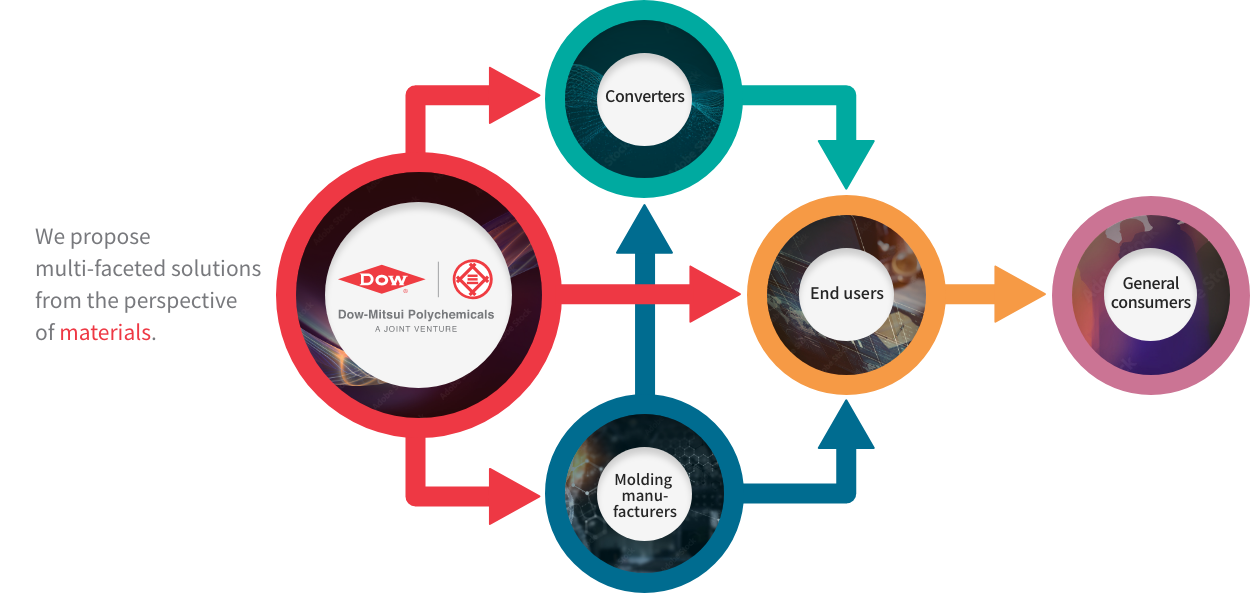

Using the latest technologies related to high-performance polymers,

we develop and propose products and solutions that best suit customers.

- Technical Center

- Safety, Health, and Environment

- Molding equipment

- Analyzer

- Measuring system

Overview of the Technical Center

History

- 1962

- Founded as the Technical Service Section (inside the Otake Plant)

- 1967

- Relocated to Chiba (Chiba Plant enters operation)

Renamed as the Technical Service Research Institute

- 1987

- Complete reconstruction of office building and molding building

Renamed as the Technical Center

- 2017

- 50th anniversary of the relocation to Chiba

Facilities

| No.1 Molding Building | 2,000㎡ |

|---|---|

| No. 2 Molding Building | 1,100 ㎡ |

| Testing Building | 1,100 ㎡ |

| Office Building | 1,850 ㎡ |

| Total | 6,050 ㎡ (floor area) |

| Total site area | 9,700 ㎡ |

Features of the Technical Center

Operating Policy

- Open research institute

(Joint development with customers, observation of prototyping)

Functions

- Development of new products, applications and markets

- Provision of high quality technical services

- Development of efficient production technologies

Capacity

- Molding equipment

(semi-commercial scale) - Well-equipped facilities to assess and analyze physical properties

Safety, Health, and Environment

Consecutive days without an accident (employee lost time injury)(As of September 9, 2021)

- Otake Plant

- 17,514 days

(47 years from September 28, 1973)

- Chiba Plant

- 9,611 days

(26 years from May 19, 1995)

- Technical Center

- 12,511 days

(34 years from June 10, 1987)

Ensuring thorough compliance with laws and regulations

Environmental initiatives

Reducing waste resin and electricity use

Installation of solar power generating system (10 kw, NEDO field test)

Qualifications and Experts

CERTIFIED PACKAGING PROFESSIONAL

Packaging

managers

1st class injection molding

technicians

Odor analysts

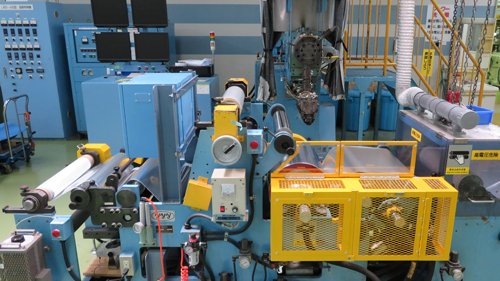

Molding equipment

Extrusion coating

- Extrusion coating molding machine

Films and sheets

- T-die cast film / sheet molding machine

- Inflation film molding machine

- Vacuum laminator

Molds

- Injection molding machine

- Extrusion blow molding machine

- Injection stretch blow molding machine

- Pressure vacuum molding machine

- Press molding machine

Compound

- Laboplast mill

- Single / twin screw extruder

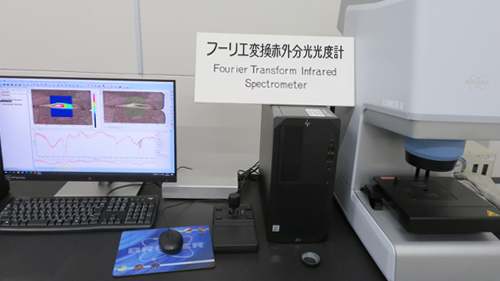

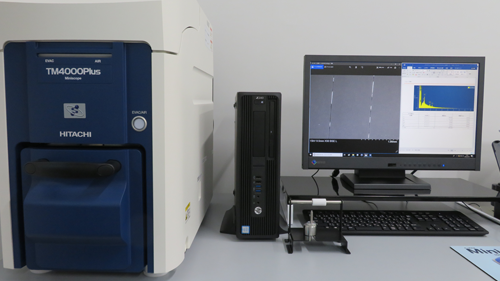

Analyzer

Microanalysis

- Microscope FT-IR (various composition analysis)

- Electron microscope: STEM (surface state, morphology)

- Tabletop microscope: tabletop SEM (surface state, morphology)

Chemical analysis

- High temperature GPC (molecular weight distribution measurement)

- HPLC (analysis of various additives)

- GC, GC/MS (Analysis of various additives and gases)

- EDX (Qualitative analysis of inorganic elements by X-ray)

- ICP-OES (Quantitative analysis of inorganic elements)

Thermal analysis

- DSC (melt point, latent heat, specific heat, oxidative induction time)

- TG/DTA (thermal decomposition starting temperature, oxidation starting temperature)

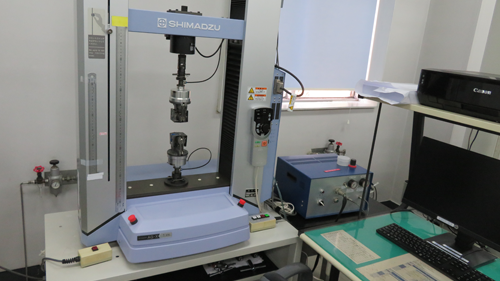

Measuring system

Mechanical properties

- Tension / cracking / peel strength

- Hardness, rigidity, wear

- Impact, rebound elasticity

Thermal properties / melt properties

- Vicat / HDT, low temperature brittleness, DVE

- MFR, melt tension, capillary

Electrical properties / optical properties

- Resistance / dielectric constant

- Haze / Trans / Gross, hue ((YI / △E)

Other properties

- Friction coefficient, specific gravity, etc.

- Gas permeability (WVTR, O2/N2/CO2)