Usage detail

- Overview

- Grade Chart

- Usage detail

- Product Safety Information

Introduction

MIRASON™ is a low density polyethylene (LDPE) produced through high-pressure radical polymerization, first manufactured through a process developed by the US-based DuPont in 1962.

| Polymerization method | High pressure process | High pressure process | |||

|---|---|---|---|---|---|

| Classification | Low density: LDPE |

Low density: LLDPE |

Medium density: MDPE |

High density: HDPE |

|

| Autoclave | Tubular | ||||

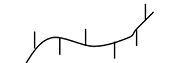

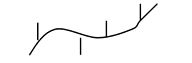

| Molecular structure | Main chain: (-CH2-CH2-)n | ||||

|

|

|

|

|

|

| Long-chain branching | Short-chain branching | ||||

| Density (kg/㎡) | 915 - 930 | 910 - 930 | 935 - 940 | 945 - 970 | |

| Melting point (ºC) | 105 - 116 | 115 - 123 | 124 - 126 | 127 - 135 | |

| Impact strength | ✕ - ◯ | ◎ | △ - ◯ | ✕ | |

| Transparency | Semi-transparent | Transparent | Transparent | Semi-transparent | Opaque |

| Rigidity | Flexible | Flexible | Somewhat rigid | Rigid | |

| Features | Excellent electrical insulation, water resistance, chemical resistance and low temperature impact strength | ||||

| Additive-free grades are possible | |||||

| Good moldability (extrusion lamination) | Good moldability (inflation) | Poor moldability (extrusion equipment, bubble stability) (particularly LLDPE), good ductility | |||

← Swipe →

Features

Due to its molecular structure, MIRASON™ has long-chain branches not found in other olefin resins, and has a characteristically large melt elasticity. Chemically, it also has good thermal stability and is widely used in the packaging materials fields such as films processed with various methods, as well as the industrial materials fields including hollow molded containers and electrical wire sheathing.

MIRASON™

| Grade | Test item | MFR | Density | Tensile stress at break | Tensile elongation at break | Bend elasticity | Durometer D hardness/th> | Vicat softening temperature | Melting point | Main applications | Food hygiene | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ◯: Listed (acquired), ✕: Not listed (not acquired) - : Unknown 1) Dow-Mitsui Polychemicals has not conducted an elution test using a food simulant-solvent. 2) Even if it is listed (acquired), there may be various restrictions and other requirements, please make sure to confirm the details with us. 3) Food hygiene information does not necessarily reflect the latest version of each law or regulation (including voluntary standards). Please be sure to confirm the details with us. |

||||||||||||||

| Measurement method | JIS K7210:1999 (190℃, 2.16 kg load) |

JIS K7112 :1999 |

JIS K7161-2/1A/50 :2014 |

JIS K7161-2/1A/50 :2014 |

JIS K7171 :2016 |

JIS K 7215 :1986 |

JIS K7206 :1999 |

(DSC) | ||||||

| Unit | g/10min | kg/㎥ | Mpa | % | Mpa | ℃ | ℃ | Positive List under the Consumer Affairs Agency , Japan |

JCII center' confirmation certificate (Voluntary standards) |

US FDA 21CFR |

European PIM |

|||

| 11P | 7 | 918 | 11 | 100 | 154 | 51 | 89 | 108 | Regular packaging | ◯ | ◯ | ◯ | ◯ | |

| 68P | 23 | 918 | 10 | 130 | 146 | 51 | 86 | 106 | Injection and extrusion molding | ◯ | ◯ | ◯ | ◯ | |

| F9673P | 1 | 919 | 14 | 90 | 172 | 55 | 93 | 110 | Regular packaging | ◯ | ◯ | ◯ | ◯ | |

| B319 | 0.3 | 921 | 19 | 520 | 336 | 11 | 56 | 109 | Hollow molding | ◯ | ◯ | ◯ | ◯ | |

| 50P | 2 | 920 | 15 | 90 | 184 | 53 | 97 | 110 | Injection and extrusion molding | ◯ | ◯ | ◯ | ◯ | |

| 3530 | 0.2 | 924 | 20 | 670 | 407 | 57 | 102 | 113 | Electric wire | ◯ | ✕ | - | ◯ | |

← Swipe →

* JCII center: Japan Chemical Innovation and Inspection Institute, Food Contact Material Safety Center.

Note: The displayed data are typical values and cannot be used as standard values.

Only typical grades are listed in this table. Please contact Dow-Mitsui Polychemicals to inquire if other grades are available.

Specimen Preparation Methods and Test Methods Regulations for PE (JIS K 6922-2)

- Japanese Industrial Standards JIS K 6922-2

- Plastics - Polyethylene (PE)

- Materials for Molding and Extrusion - Part 2: Methods of Preparing Test Specimens and Determining Properties

- For PE with MFR of 1g/10min or more, the specimen shall be prepared by injection molding.

- For PE with MFR less than 1g/10min, prepare specimens by compression molding.

- Mechanical properties: Tensile properties are specified in JIS K 7161-2 for test method and JIS K 7139 for test specimen.

Specimen specifications for PE during tensile testing (JIS K 7139)

- Japanese Industrial Standards JIS K 7139

- Plastics - Test Specimens

- Injection molding of test specimens shall be performed in accordance with the provisions of JIS K 7152-1 or JIS K 7154-1. (Molding method and conditions specified)

- Compression molding of test pieces shall be in accordance with JIS K 7151 or ISO 295. (Method and conditions for molding)

- Type A1 specimens (injection molded multi-purpose specimens) should be used for testing.

Test condition regulations for PE during tensile testing (JIS K 7161-2)

- Japanese Industrial Standards JIS K 7161-2:2014 (ISO 527-2:2012)

- Plastics - Determination of Tensile Properties - Part 2: Test Conditions for Molded, Extruded and Cast Plastics

- Use multipurpose specimens of Type 1A if the specimens are directly mold-formed, or Type 1B if the specimens are prepared by machining. Specimen 1A may be compression molded. When small specimens are used, JIS K 7139 shall be used.

- The type of test specimen and test speed shall be as follows Tensile test JIS K 7161-2/1A/50

Usage detail

MIRASON™ is used as a material for the following kinds of products.

Bottle caps

Electric wire sheathing

Product Safety Information

1. Medical applications

Please do not use this product for permanent implantation in the human body or for medical applications involving a state of permanent contact with bodily fluids or human tissue (in this case, permanent means 30 days or more.)

Additionally, please consult with Dow-Mitsui Polychemicals in advance if you wish to use the product for other medical applications, such as for a medical device as defined in the Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices.

2. Food packaging applications

Please contact Dow-Mitsui Polychemicals regarding the state of inclusion in (conformity to) domestic and overseas laws or regulations regarding food utensils, containers and packaging materials.